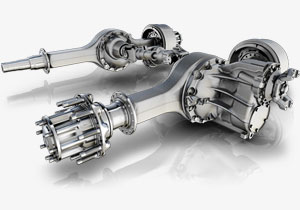

Detroit™ Rear Axles: Designed for Long Roads

Our new Detroit™ rear truck axles are designed to stand apart from the competition.

An integrated one-piece differential eliminates the need for a head bearing, allowing for a larger main differential and greater stability and durability.

An integrated one-piece differential eliminates the need for a head bearing, allowing for a larger main differential and greater stability and durability.

Our gears are precision cut using a power dry cutting process followed by a grinding process. This ensures a consistent gear mesh resulting in more efficient power transfer. You’ll get a quieter truck axle and better gear mesh for driving comfort and durability.

On our tandem rear truck axles, the oil deflector provides full lubrication at low speeds for greater reliability and gear protection. The gears naturally push oil out, while the deflector catches it and moves it back to the top of the inter-axle differential, providing necessary lubrication without an oil pump.

Topoid gearing reduces driveline vibrations and wear, providing greater reliability and driver comfort.

New Input Seal Design

Separating the seal from the threaded ring provides greater sealing and leak protection. This significantly reduces oil leakage and eliminates the need for sealant on the threaded ring.

Mix and Match

Our intermediate track housing allows for wide-based tires. The axles allow you to switch back and forth between dual or single tires. Beyond convenience (or necessity) this flexibility boosts your resale value, too.

Maintain Traction in All Conditions

Optionally, you can add Driver Controlled Differential Locks (DCDL) for improved traction on snow and ice, and the TracTech NoSpin Automatic Locking Differential to improve driving on low traction surfaces. These options prevent wheel spin and power loss when one wheel loses traction and to compensate for differences in wheel travel when turning.

To learn more about our rear truck axles, visit our website.