Detroit Medium Duty: Application & Quality

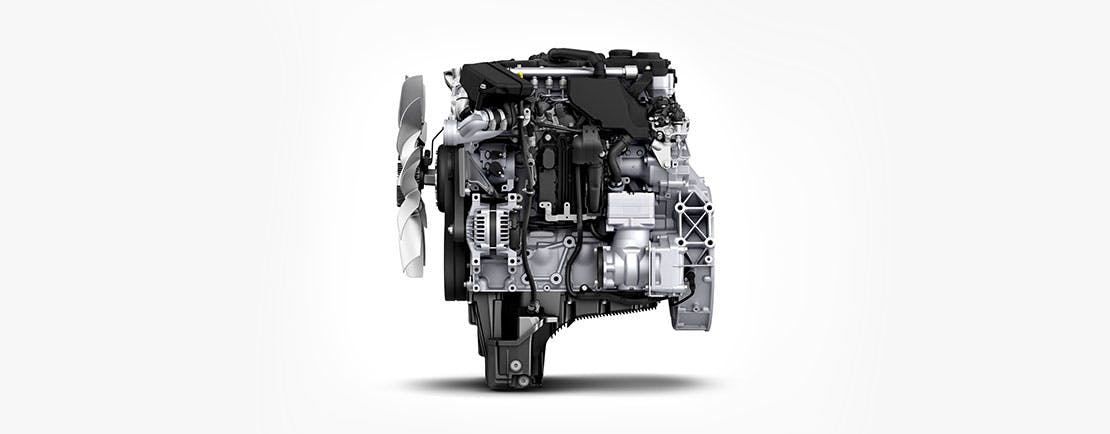

Detroit is proud to unveil the 5.1-liter DD5™, the trucking industry’s first four-cylinder engine for a conventional-cab, medium-duty vocational truck. Quality-focused engine design means comprehensive optimization, with micron-level engineering accuracy and attention to detail. Two fewer pistons deliver fuel efficiency savings without sacrificing power or performance.

Debuting this fall in the versatile, popular Freightliner model M2106—the DD5 is the first in-house engine from the new Detroit™ medium-duty engine group (MDEG). Available at launch for pickup and delivery application in 210 HP, 575-lb-ft and 230 HP, 660-lb-ft ratings, the DD5 will eventually power a variety of vocational applications. Variable cam phasing (VCP) technology, unique to the DD5, will help optimize thermal management for improved aftertreatment performance, essential in low-load, stop-and-go applications like pickup and delivery.

Built on the same Detroit heavy-duty engine platform that forged the successful DD13®, DD15® and DD16®engines, the DD5 will feature a deep, robust, noise-minimizing, lightweight rib block and best-in-class fuel efficiency—three percent better than its closest competitor—as well as the Detroit™ Connect Virtual TechnicianSMremote diagnostics system. Maintenance intervals are minimized with easily accessible, cartridge-style fuel and oil filters mounted above the rail for easy access. Oil and filter changes are only required every 45,000 miles.

Extensive DD5 development and testing has resulted in a B10 life of 400,000 miles, with a three-year, 250,000-mile engine and aftertreatment system warranty. The DD5 meets GHG2017 gas and fuel-efficiency standards, with less complexity and fewer parts for better endurance, reliability, fuel efficiency and durability.